Consulting

Our experience ranges from delivering small self-contained work packages to managing complex multi-disciplinary projects with a large number of stakeholders.

Our services

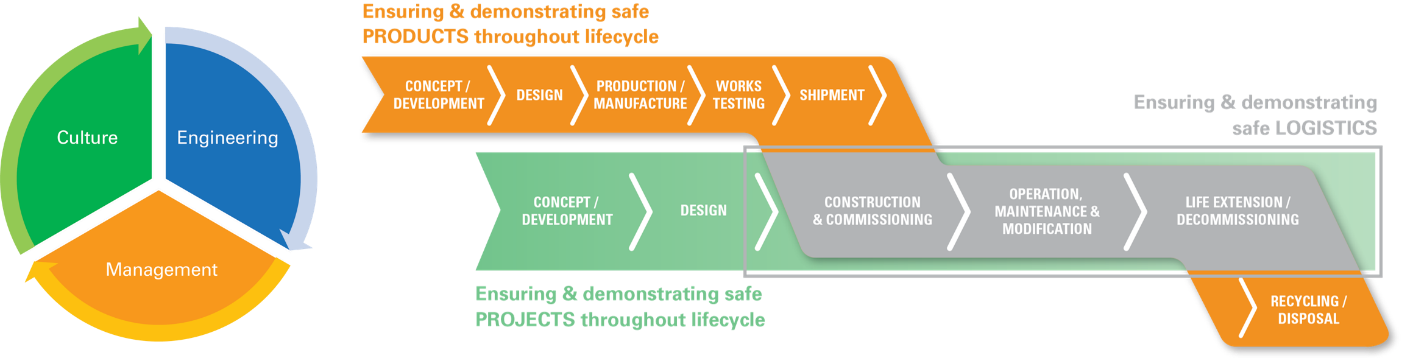

Our services recognise that controlling risk requires understanding engineered and technological systems, management systems and organisational, cultural and behavioural factors.

We work across the entire lifecycle of facilities and equipment

Our services

Our services recognise that controlling risk requires understanding engineered and technological systems, management systems and organisational, cultural and behavioural factors.

We work across the entire lifecycle of facilities and equipment

Engineering

We provide a comprehensive range of services to identify, analyse, evaluate and reduce the risks associated with facilities, operations and equipment to acceptable levels.

Management

We deliver a broad range of management system services to identify, develop and implement effective policies and procedures to maintain control of risks and minimise loss.

Culture

We provide a range of services to accelerate cultural and behavioural improvement, and ensure a solid foundation for building sustainable improvements in risk control.

Our industries

Our expertise is particularly suited to companies and organisations operating in the high hazard industries and other sectors where the impact of loss is high. Our consultants have considerable international experience, and our multi-industry expertise facilitates the sharing of good practice.

Our deliverables

Our deliverables range from assessments for specific risk issues, through formal safety cases for large industrial facilities, to entire management system documentation, and multi-year training, cultural and implementation support.

Consulting tools

To add value to our consulting services, we use a wide range of standard and customised risk and HSSE tools, both digital and non-digital.

Risk Assessment Methods

FMEA

Failure Modes and Effects Analysis (FMEA) seeks to identify hazards by identifying potential failure modes of the various parts of a system, the effects these failures may have on the system, the mechanisms of failure and how to avoid the failures and/or mitigate the effects of the failures. FMECA extends an FMEA so that each fault mode identified is ranked according to its Criticality (importance).

Although originally intended for equipment items, it has also been adapted for procedures and software for example. It is very good at identifying single point failure modes, but not combinations of failure modes or common cause failure.

Our FMEA/FMECA services include:

- Facilitating and recording FMEA/FMECA workshops

- Conducting standalone FMEA/FMECA studies

- Qualitative reviews describing the causes/consequences of failure

- Criticality reviews to determine the importance of each failure

- Quantitative reviews to derive Mean Time To Failure (MTTF) and Mean Time To Repair (MTTR) for input into a reliability/availability study

Functional safety

Electrical, electronic and programmable electronic (E/E/PE) safety-related systems play a crucial role at industrial facilities in managing risk to tolerable levels. GSC® considers the complete lifecycle of safety-related and business-critical systems, including concept, requirements, planning, specification, design, commissioning, operation, maintenance and decommissioning phases.

GSC® consultants use a range of recognised techniques to assure the performance of these systems in managing operational risks.

Our services include:

- System specification

- Independent safety assessment and audit

- Hazard identification (e.g. HAZOP, FMEA, FMECA, human error review)

- Causal and consequence analysis (e.g. fault tree analysis, event tree analysis)

- SIL assessment and verification

- Layer of protection analysis (LOPA)

- Identifying safety-critical elements and developing performance standards and verification schemes

- Design substantiation of safety requirements

- Options analysis

- ALARP assessment

- Due diligence for acquisitions, mergers and business ventures

- TÜV Rheinland certified training for Functional Safety Engineer (Process Hazard & Risk Analysis)

- Training courses

Hazard identification

Hazard identification is the first and, in many ways, the most important step in a risk assessment. If a hazard is not identified, it is unlikely to be managed effectively.

Different industries, applications and lifecycle timings demand different solutions and many different tools for identifying hazards have been developed. Some have wide applicability, others are very narrow in scope or have been developed for one-off applications, equally the level of detail and documentation ranges from the very extensive to the bare minimum.

GSC® provide a full portfolio of services for the formal, systematic and comprehensive identification of hazards:

- HAZID studies

- HAZOP studies

- FMEA and FMECA

- Plant ‘walkdowns’ and surveys

- Hazard registers and fault schedules

- Risk ranking and risk assessment

- Incident analysis and human factors reviews

- Training courses

HSSE / safety cases

A Health, Safety, Security & Environmental (HSSE) / safety case aims to demonstrate to all stakeholders that adequate controls are in place to ensure that the risks associated with a high hazard facility are both tolerable and reduced to acceptable levels.

GSC® provides a comprehensive service for the planning, production and presentation of all levels of HSSE case documentation for all high hazard industries, defence, oil & gas, chemical and transport. Each HSSE case takes into account the unique requirements specific to the industry, and relevant legislation, regulations and corporate standards.

Our services cover:

- Co-ordination, planning, preparation and technical support for all aspects of HSSE / safety case

- Updates throughout facility lifecycle

- Regulatory compliance review

- Hazard identification

- Deterministic and probabilistic assessment

- Modelling of fault and hazard conditions

- Frequency and consequence assessment

- Identification of operating limits and conditions

- Design substantiation

- Preparation of emergency plans

- Cost-benefit analysis and ALARP assessment

- HSSE / safety management system support

- Preparation of HSSE / safety case reports

- Roll-out, communication and training for HSSE / safety cases

- Independent periodic / thorough review

- Electronic ‘living’ HSSE / safety cases

- Live risk monitoring solutions

- Training courses